Tough Precision Material Slate Grey for MakerBot Method

Tough Precision Material Slate Grey for MakerBot Method

What's in the Box:

1 Spool of Tough Precision Model Material

TEMPERATURES

- Glass Transition Temperature: 60-65°C (140-149°F)

- Melting Temperature: 150-160°C (302-320°F)

- Extruder Temperature: 210°C (419°F)

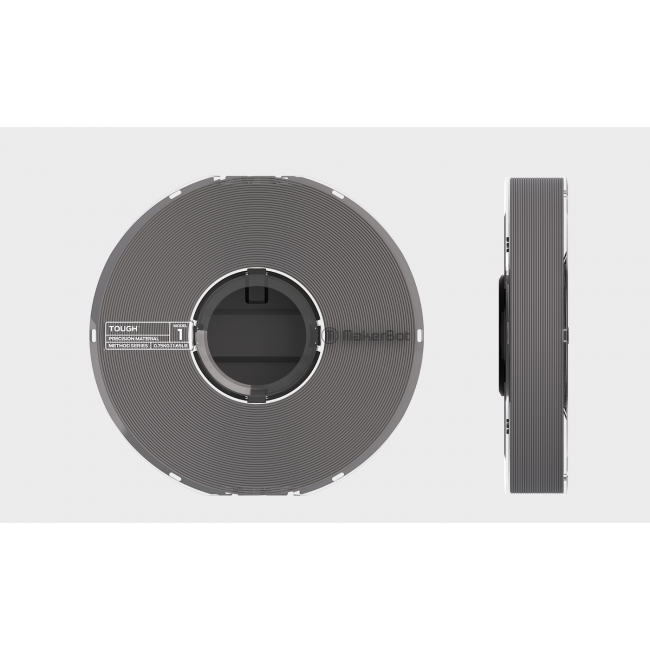

DIMENSIONS AND WEIGHT

- Spool Diameter: 21.8 cm (8.6 in)

- Spool Width: 4.2 cm (1.65 in)

- Material Diameter: 1.75 mm

- Shipping Weight: 1.1 kg (2.4 lb)

- Net Weight: 0.75 kg (2 lb)

PRINTER COMPATIBILITY

MakerBot Method

MATERIAL TYPE

Tough Precision Model Material: Extensively-tested for the highest reliability and measurably accurate parts.

SPOOL TYPE

Smart Spool™ provides valuable information including material type, color, and amount remaining via an RFID chip directly to MakerBot Print, while a desiccant in the spool maintains a low moisture level inside the drawer bay.

SOFTWARE COMPATIBILITY

MakerBot Print

OPERATING ENVIRONMENT

Store MakerBot Method Tough Precision Material in the included a vacuum-sealed metalized polyester bag to avoid moisture absorption from air; long-term exposure to humidity can compromise material quality and performance. Make sure the built-in desiccant is in the spool to absorb any moisture exposure during the material loading process.

ABOUT THE MAKERBOT METHOD

MakerBot Method, the first performance 3D printer bridging the gap between industrial and desktop 3D printing. Industrial Reliability + Precision, Fastest CAD to Part, Maximum Innovation + Minimal Investment. Developed from the ground up leveraging industry-leading Stratasys® patents including a heated build chamber, precision dissolvable supports, and dry-sealed material bays.

Dry-Sealed Material Bays

Dry-Sealed Material Bays form a near-perfect seal to keep material free of damaging humidity. A suite of built-in sensors provides that your material is stored in its optimal environment—a feature previously only available in industrial 3D printers.

MakerBot Materials for Method

PRECISION MATERIALS: Extensively tested by MakerBot for the highest reliability and measurably accurate parts.

SPECIALTY MATERIALS: For users looking for special materials with advanced properties to push the limits of what's possible.

| Manufacturer | Makerbot |

|---|