Unitree - R1 Humanoid Robot (Basic, Edu, Standard, Smart, Pro, U1, U2, U3, U4, U5, U6)

From £7,104.00 £5,920.00

To £26,640.00 £22,200.00

R1 Basic

The R1 Basic is the least capable of the R1 line, with 24 total DOF and without programming capabilities is not intended for research, it's best for demonstration and events. If you don't need a robot that is able to be programmed the basic might be a good choice.

R1 EDU Standard (U1)

The R1 Edu Standard (U1) comes with 24 total DOF and the ability to be programmed, with a 40 TOPS compute module.

R1 EDU Smart (U2)

The R1 EDU Smart (U2) is similar to the EDU Standard (U1) but comes with 2 more DOF (head) making a total of 26 DOF, the other difference is the compute module of 100TOPS.

R1 EDU Pro A (U3)

The R1 EDU Pro A (U3) is similar to the R1 EDU Smart (U2) but comes with 2 Dex3 (7 actuated DOF Dexterous hands without tactile sensors) making a total of 40 DOF (26+7+7)

R1 EDU Pro B (U4)

The R1 EDU Pro B (U4) is similar to the R1 EDU Pro A (U3)but the hands come with 33 tactile sensors.

R1 EDU Pro C (U5)

The R1 EDU Pro C (U5) is similar to the R1 EDU Smart (U2) but comes with 2 BrainCo Revo 2 Basic hands (6 actuated DOF Dexterous hands without tactile sensors) making a total of 38 DOF (26+6+6)

R1 EDU Pro D (U6)

The R1 EDU Pro D (U6) is similar to the R1 EDU Pro C (U5) but comes with 2 BrainCo Revo 2 Touch hands (6 actuated DOF Dexterous hands with tactile sensors) making a total of 38 DOF (26+6+6)

| Model | R1 Basic | R1 EDU Standard U1 | R1 EDU Smart U2 | R1 EDU Pro A U3 | R1 EDU Pro B U4 | R1 EDU Pro C U5 | R1 EDU Pro D U6 |

| Total Degrees of Freedom (DOF, Actuated) | 24 | 22 | 26 | 40(26+7+7) | 38(26+6+6) | ||

| Head Degrees of Freedom | / | 2 | |||||

| Dexterous Hand | / | 2 × Dex3 (without tactile) | 2 × Dex3 (with 33 tactile sensor) | Brainco Revo 2 Basic | Brainco Revo 2 Touch | ||

| Hand DOF (per hand) | / | 7 | 6 | ||||

| Hand DOF (per hand) | / | img | img | ||||

| Compute Module | / | 40 TOPS | 100 TOPS | ||||

| SDK / Dev Support | No | Yes (High-level/Low-level interfaces, supports Issac Sim, etc.) | |||||

| Warranty Period [3] | 8 Months | 12 Months | |||||

| Max Payload (per arm) | 2 kg | 2 kg (Improving) | |||||

| Height, Width and Thickness (Stand) | 1210x357x190mm | ||||||

| Weight (With Battery) | About 25kg | ||||||

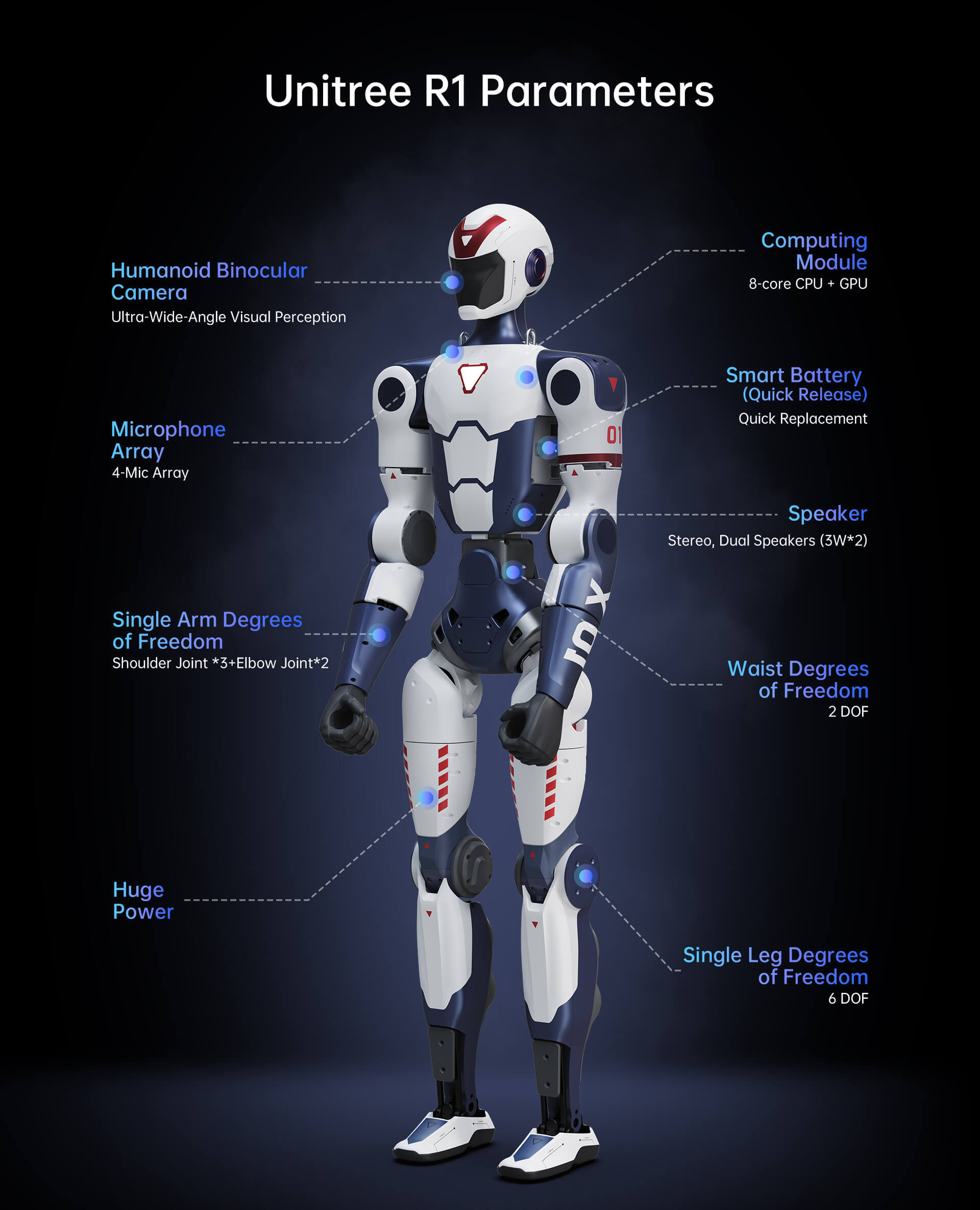

| Single Leg Degrees of Freedom | 6 | ||||||

| Single Arm Degrees of Freedom | 5 | ||||||

| Waist Degrees of Freedom | 2 | ||||||

| Stereo Camera | YES | ||||||

| Microphone Array | 4-Mic Array | ||||||

| Speaker | YES | ||||||

| Wireless | Wifi6, Bluetooth 5.2 | ||||||

| Smart Battery (Quick Release) | YES (Lithium) | ||||||

| Battery Life | About 1h | ||||||

| Wiring | Hollow + Internal wiring | ||||||

| Joint Encoders | Dual + single encoder | ||||||

| Joint bearings | Crossed roller bearings, Double-row Ball Bearings | ||||||

| Joint motors | Low inertia high-speed internal rotor PMSM (permanent magnet synchronous motor) | ||||||

| Forearm + Upper Arm Length | 435 mm | ||||||

| Shank + Thigh Length | 675 mm | ||||||

| Upgraded Intelligent OTA | YES | ||||||

| Joint Movement Space | Waist Joint: Y±150° R±30° Knee Joint: -10° ~+148° Hip Joint: Y±157° P:-168° ~+146° R:-60° ~+100° |

||||||

| Cooling System | Local air cooling | ||||||

| Packing List |

1* Robot |

1* Robot |

|||||

Unitree R1 vs Unitree G1

Summary

R1 Designed for research and global developer engagement, R1 is considered a revolutionary product that will reshape market rules and accelerate ecosystem growth.

While both the Unitree R1 and G1 humanoid robots fall under the category of embodied intelligence, they feature significant differences in their design philosophy, technical implementation, and market positioning. From a professional perspective, these distinctions go beyond simple parameter comparisons and highlight fundamental differences in their task execution capabilities, commercial application potential, and product maturity.

Arm Degrees of Freedom (DOF)

| R1 | G1 |

| Single arm with 5 DOF | Single arm with 7 DOF |

The DOF of a robotic arm is a core indicator of its kinematic redundancy. A 5-DOF arm is typically sufficient to position and orient its end-effector in 3D space, but its movement paths are relatively fixed and constrained. The G1's 7-DOF arm, however, introduces an extra redundant joint. This redundancy is crucial as it allows the arm to alter its configuration while maintaining a constant end-effector position and orientation. This means the G1 can navigate around obstacles and find optimal paths in confined or complex environments to perform manipulation tasks. This provides the G1 with a level of flexibility and adaptability that the R1 lacks, particularly in applications like industrial assembly or precise lab operations where path planning is critical.

Single Arm Payload

| R1 | G1 |

| Max. single arm payload of 2 kg | Max. single arm payload of 3 kg |

Payload capacity is a direct measure of a robot's power performance and structural rigidity. The G1's 3 kg payload not only allows it to handle heavier objects but, more importantly, enables it to maintain high precision and stability even when operating near its load limit. In industrial applications, such as handling tools, components, or sorting materials, a higher payload capacity translates to greater operational efficiency and a wider range of compatible tasks. Compared to the R1, the G1 demonstrates superior practicality and reliability in scenarios that require handling moderately heavy loads.

Waist Degrees of Freedom

| R1 | G1 |

| Up to 2 DOF | 3 DOF |

Waist DOF (typically yaw, pitch, and roll) is a key factor influencing a humanoid robot's overall motor coordination and upper-body workspace. A 3-DOF waist design, as found in the G1, allows the robot to finely adjust its center of gravity and torso posture during arm movements. This expands the arm's operational envelope and enhances overall dynamic stability. Consequently, the G1 can execute tasks over a wider range or in restricted spaces with more optimized posture, reducing unnecessary movements and improving efficiency. The R1's 2-DOF waist is comparatively limited in its posture adjustment and workspace.

Battery Endurance

| R1 | G1 |

| 1 hr. | 2 hrs. |

Battery endurance is a critical operational parameter that determines a robot's working efficiency and practical utility. The G1's two-hour runtime, double that of the R1, means it can complete longer continuous tasks with less frequent charging. In commercial and industrial deployments, this significantly reduces downtime for charging, thereby boosting task coverage and overall productivity. This is a decisive advantage for commercial clients seeking high efficiency and low operational costs.

Conclusion

Based on this detailed analysis, the Unitree G1 demonstrates a clear superiority over the R1 in crucial robotic performance metrics, including manipulation dexterity, payload capacity, motor coordination, and battery endurance. These technical advantages position the G1 to handle more complex and demanding commercial and industrial applications.

| Manufacturer | Unitree |

|---|