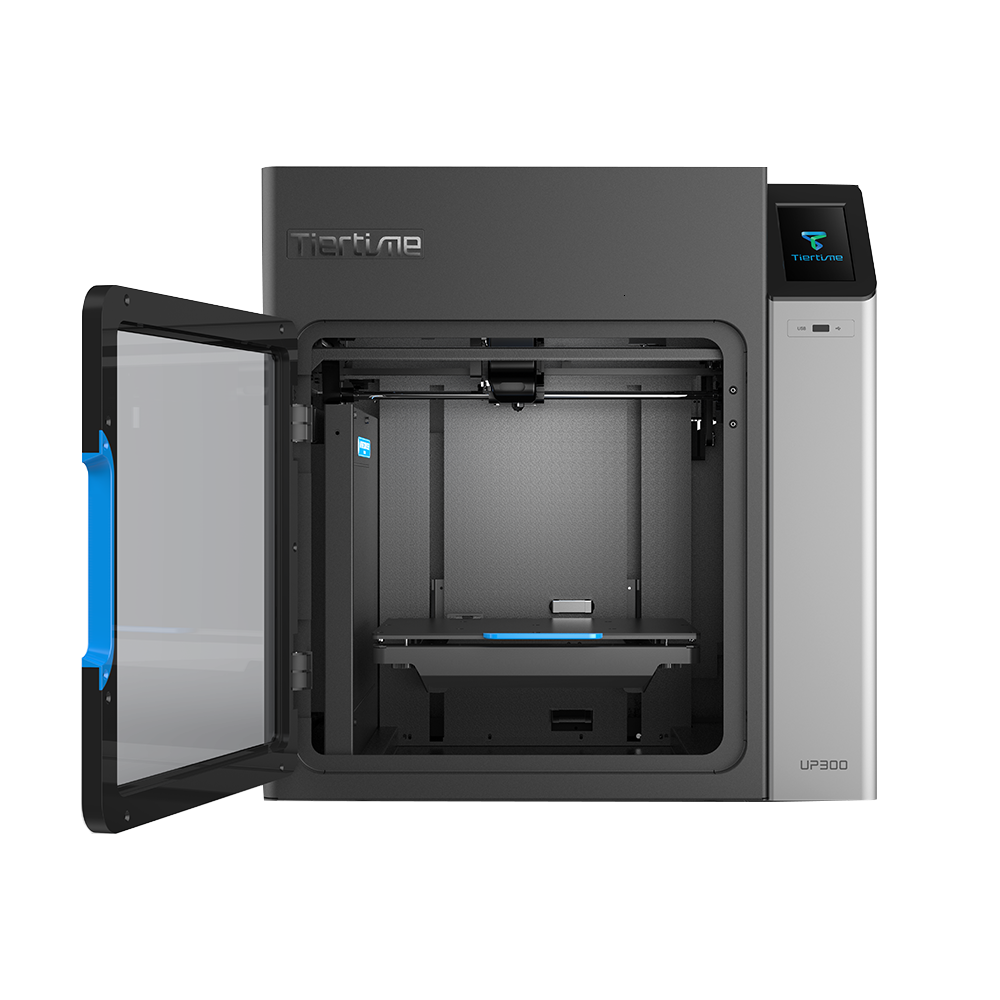

Tiertime UP300

The Tiertime UP300 answers the need of users that require large build volumes and consistent performance across different materials. It is a combination of new innovations and improved reliable features for which Tiertime has been known : Three material-specific print heads for filaments ABS, PLA and TPU, double-sided interchangeable build plates, dual air filtration, and compatibility with Tiertime Print Queue.

| Accuracy | 50 microns (0,05 mm/layer) |

| Build volume | 205 x 255 x 225 mm |

| Speed | Up to 200 mm/second |

| Compatible materials | Tiertime ABS / Tiertime PLA / Tiertime TPU /ABS Zortrax / M3D ABS / M3D PLA and foreign filaments |

3D UP300 on video

Material-Specific Print Heads optimized for Different Materials

The UP300 comes with three different print extruders each one is designed to work with a specific material type. The first extruder is for ABS and other high temperature filaments. The second extruder is for lower temperature filaments such as PLA. The third extruder is for TPU, a flexible polyurethane.

Double-Sided Interchangeable Build Plates

The UP300 3D printer is equipped with a reversible double-sided plate. Made of glass, the first side is preferred for 3D printing without rafts (rafts) and obtaining a perfectly smooth first layer of printing. The second side is a perforated plate. Greatly increasing the adhesion of printed models, it is ideal for 3D printing of large geometric parts printed in ABS plastic filament, sensitive to heat.

HEPA filter + Carbon filter

The Tiertime brand UP300 3D printer includes the dual air filtration system specially designed for its large print chamber. The air is filtered by HEPA filter and separate activated carbon filter which drastically reduce toxic emissions. HEPA filter promises 99.95% efficient filtration for ultrafine particles.

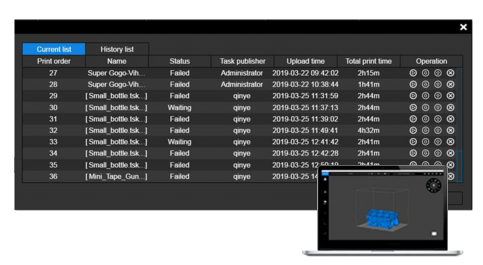

Tiertime Print Queue

This feature allows multiple users to send their ready-to-print files from different sources to the same machine via USB / WIFI / LAN. Sending files to print files from a variety of sources to a 3D printer can be complex and time consuming. If there is only one 3D printer in the office and multiple designers want access to it, they will have to constantly monitor the machine. Users have to wait for files to be sent to the printer and printed, which could take hours. Tiertime Print Queue allows multiple users to send files to the printer simultaneously. First come, first served ! The files that will be printed will appear in the waiting list.

UP STUDIO slicing software

From the UP print preview software, configure your prints with ease!

You can position your 3D model in the ideal direction for printing, configure the thickness of the layers, filling between layers and much more. The software also allows you to convert an image 2D as 3D file. This software also exists in the form of an Apple mobile application.

Available on Mac and PC

Technical specifications

Physical dimensions of Tiertime UP 300

| Dimensions | 500 x 523 x 460 mm |

| Weight | 30 kg |

| Package weight | 42.5 kg |

| Technology | MEM (Melted Extrusion Modelling) |

| Extruder | Simple |

| Printing speed | 200 mm/sec |

| Buildplate volume | 205 x 255 x 225 mm |

| Resolution | 50 - 400 microns |

| Filament diameter | 1,75 mm |

| Nozzle diameter | 0,4 mm |

| Plate | Reversible: perforated, glass / Heated |

Software

| Version | UP Studio Version 2.5 and more |

| Supported files | .stl, .obj, .up3, .tsk, .3mf, .ply, .off, .3ds |

| Compatible | Mac OS 10.10, Windows 7 and more |

| Connectivity | WI-FI, ethernet, USB cable, USB key |

Temperatures

| Max. extruder temperature | 299 °C |

| Max. plate temperature | 100 °C |

| Ambient operating temperature | 20 - 30 °C |

| Storage temperature | 0 - 35 °C |

Consumption

| AC Input | 240 [V] AC, 50/60 [Hz] 110 [V] AC, 50/60 [Hz] |

| Consumption | 220 W |

| Manufacturer | Tiertime |

|---|